Wholesale China Sulfate Removal Ion Exchange Resin Company Factories - Inert and Polymer beads – Dongli

Wholesale China Sulfate Removal Ion Exchange Resin Company Factories - Inert and Polymer beads – Dongli

Wholesale China Sulfate Removal Ion Exchange Resin Company Factories - Inert and Polymer beads – Dongli Detail:

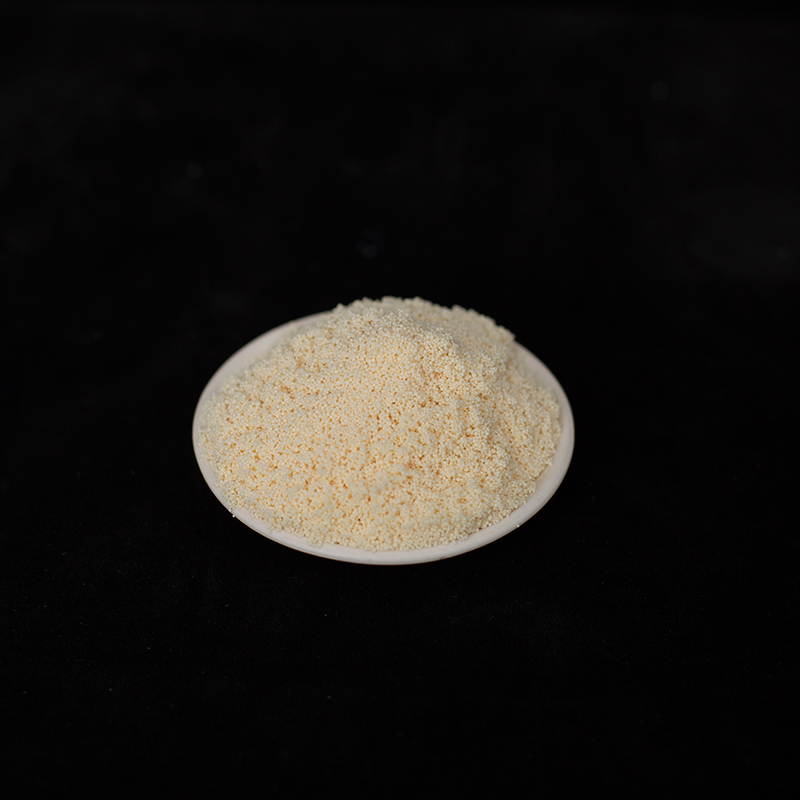

Inert Resin

| Resins | Polymer Matrix Structure | Physical Form Appearance | Particle Size | Specific Gravity | Shipping Weight | Wear ability | Leachable |

| DL-1 | Polypropylene | White Spherical Beads | 02.5-4.0mm | 0.9-0.95 mg/ml | 300-350 g/L | 98% | 3% |

| DL-2 | Polypropylene | White Spherical Beads | Φ1.3±0.1mmL1.4±0.1mm | 0.88-0.92 mg/ml | 500-570 g/L | 98% | 3% |

| STR | Polypropylene | White Spherical Beads | 0.7-0.9mm | 1.14-1.16 mg/ml | 620-720 g/L | 98% | 3% |

This product has no active group and no ion exchange function. The relative density is generally controlled between the anion and cation resins to separate the anion and cation resins and avoid the cross contamination of the anion and cation resins during regeneration, so as to make the regeneration more complete.

Inert resin is mainly used for water treatment with high salt content; Large amount of water softening and dealkali treatment; Neutralization of waste acid and alkali; Treatment of electroplating wastewater containing copper and nickel; It can also be used for the recovery and treatment of waste liquid, the separation and purification of biochemical drugs. Many people are not clear about the function and use of inert resins. Let’s take a look at the following:

1. It plays the role of regenerant distribution during regeneration.

2. During operation, it can intercept the fine resin to avoid blocking the outlet hole or the gap of the filter cap.

3. Adjust the resin filling rate. The quality of floating bed is related to resin filling rate. The filling rate is too small to form a bed; If the filling rate is too high, the resin will be filled up after transformation and expansion, and the white ball can play a small role in regulating.

Precautions for Use of Inert Resin

This kind of resin is very stable under normal storage and use conditions. It is insoluble in water, acid, alkali and organic solvents, and does not react with them.

1. Handling, loading and unloading operations should be gentle, stable and regular, do not hit hard. If the ground is wet and slippery, pay attention to prevent slipping.

2. The storage temperature of this material should not be higher than 90 ℃, and the service temperature should be 180 ℃.

3. The storage temperature is above 0 ℃ in wet state. Please keep the package well sealed in case of water loss during storage; In case of dehydration, the dry resin should be soaked in ethanol for about 2 hours, cleaned with clean water, and then repackaged or used.

4. Prevent the ball from freezing and cracking in winter. If freezing is found, melt slowly at room temperature.

5. In the process of transportation or storage, it is strictly forbidden to stack with odors, toxic substances and strong oxidants.

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Wholesale China Sulfate Removal Ion Exchange Resin Company Factories - Inert and Polymer beads – Dongli , The product will supply to all over the world, such as: Japan, United Arab emirates, Croatia, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.