Wholesale China Mixed Bed Deionizer Company Factories - Mixed Bed Resin – Dongli

Wholesale China Mixed Bed Deionizer Company Factories - Mixed Bed Resin – Dongli

Wholesale China Mixed Bed Deionizer Company Factories - Mixed Bed Resin – Dongli Detail:

Mixed Bed Resins

| Resins | Physical Form and Appearance | Composition | FunctionGroup | Ionic Form | Total Exchange Capacity meq/ml | Moisture Content | Ion Conversion | Volume Ratio | Shipping Weight g/L | Resistance |

| MB100 | Clear Spherical Beads | Gel SAC | R-SO3 | H+ | 1.0 | 55-65% | 99% | 50% | 720-740 | >10.0 MΩ |

| Gel SBA | R-NCH3 | OH- | 1.7 | 50-55% | 90% | 50% | ||||

| MB101 | Clear Spherical Beads | Gel SAC | R-SO3 | H+ | 1.1 | 55-65% | 99% | 40% | 710-730 | >16.5 MΩ |

| Gel SBA | R-NCH3 | OH- | 1.8 | 50-55% | 90% | 60% | ||||

| MB102 | Clear Spherical Beads | Gel SAC | R-SO3 | H+ | 1.1 | 55-65% | 99% | 30% | 710-730 | >17.5 MΩ |

| Gel SBA | R-NCH3 | OH- | 1.9 | 50-55% | 95% | 70% | ||||

| MB103 | Clear Spherical Beads | Gel SAC | R-SO3 | H+ | 1.1 | 55-65% | 99% | 1 * | 710-730 | >18.0 MΩ* |

| Gel SBA | R-NCH3 | OH- | 1.9 | 50-55% | 95% | 1 * | ||||

| MB104 | Clear Spherical Beads | Gel SAC | R-SO3 | H+ | 1.1 | 55-65% | 99% | Inner Cooling Water Treatment | ||

| Gel SBA | R-NCH3 | OH- | 1.9 | 50-55% | 95% | |||||

| Footnote | * Here is equivalent; Influent rinse water quality : > 17.5 MΩ cm; TOC< 2 ppb | |||||||||

The super pure water mixed bed resin is composed of gel type strong acid cation exchange resin and strong alkali anion exchange resin, and has been regenerated and ready mixed.

It is mainly used in the direct purification of water, the preparation of pure water for electronic industry, and the subsequent mixed bed fine treatment of other water treatment processes. It is suitable for various water treatment fields with high effluent requirements and without high regeneration conditions, such as display equipment, calculator hard disk, CD-ROM, precision circuit board, discrete electronic equipment and other precision electronic products industry, medicine and medical treatment, cosmetics industry, precision machining industry, etc

Use of reference indicators

1, pH range: 0-14

2. Allowable temperature: sodium type ≤ 120, hydrogen ≤ 100

3, expansion rate%: (Na + to H +): ≤ 10

4. Industrial resin layer height M: ≥ 1.0

5, regeneration solution concentration%: nacl6-10hcl5-10h2so4: 2-4

6, regenerant dosage kg / m3 (industrial product according to 100%): nacl75-150hcl40-100h2so4: 75-150

7, regeneration liquid flow rate M / h: 5-8

8, regeneration contact time m inute:30-60

9, washing flow rate M / h: 10-20

10, washing time minute: about 30

11, operating flow rate M / h: 10-40

12, working exchange capacity mmol / L (wet): salt regeneration ≥ 1000, hydrochloric acid regeneration ≥ 1500

Mixed bed resin is mainly used in water purification industry for polishing process water to achieve demineralization water quality (such as after reverse osmosis system). The name of mixed bed includes strong acid cation exchange resin and strong base anion exchange resin.

Function of Mixed Bed Resin

Deionization (or demineralization) only means the removal of ions. Ions are charged atoms or molecules found in water with net negative or positive charges. For many applications that use water as a rinsing agent or component, these ions are considered impurities and must be removed from the water.

Positively charged ions are called cations, and negatively charged ions are called anions. Ion exchange resins exchange unwanted cations and anions with hydrogen and hydroxyl to form pure water (H2O), which is not an ion. The following is a list of common ions in municipal water.

Working Principle of Mixed Bed Resin

Mixed bed resins are used to produce deionized (demineralized or “Di”) water. These resins are small plastic beads composed of organic polymer chains with charged functional groups embedded in the beads. Each functional group has a fixed positive or negative charge.

Cationic resins have negative functional groups, so they attract positively charged ions. There are two types of cation resins, weak acid cation (WAC) and strong acid cation (SAC). Weak acid cation resin is mainly used for dealkalization and other unique applications. Therefore, we will focus on the role of strong acid cation resin used in the production of deionized water.

Anionic resins have positive functional groups and therefore attract negatively charged ions. There are two types of anion resins; Weak base anion (WBA) and strong base anion (SBA). Both types of anionic resins are used in the production of deionized water, but they have the following different characteristics:

When used in the mixed bed system, WBA resin can not remove silica, CO2 or has the ability to neutralize weak acids, and has a pH lower than neutral.

The mixed bed resin removes all anions in the above table, including CO2, and has a higher than neutral pH when used in a dual independent bed system due to sodium leakage.

Sac and SBA Resins Are Used In The Mixed Bed.

In order to produce deionized water, the cation resin is regenerated with hydrochloric acid (HCl). Hydrogen (H +) is positively charged, so it attaches itself to negatively charged cationic resin beads. The anion resin was regenerated with NaOH. Hydroxyl groups (OH -) are negatively charged and attach themselves to positively charged anionic resin beads.

Different ions are attracted to resin beads with different strength. For example, calcium attracts cationic resin beads more strongly than sodium. The hydrogen on the cationic resin beads and the hydroxyl on the anionic resin beads have no strong attraction to the beads. This is why ion exchange is allowed. When the positively charged cation flows through the cationic resin beads, the cation exchange is hydrogen (H +). Similarly, when the anion with negative charge flows through the anion resin beads, the anion exchanges with hydroxyl (OH -). When you combine hydrogen (H +) with hydroxyl (OH -), you form pure H2O.

Finally, all the exchange sites on the cation and anion resin beads are used up, and the tank no longer produces deionized water. At this point, the resin beads need to be regenerated for reuse.

Why choose mixed bed resin?

Therefore, at least two types of ion exchange resins are needed to prepare ultrapure water in water treatment. One resin will remove positively charged ions and the other will remove negatively charged ions.

In the mixed bed system, cationic resin is always in the first place. When the municipal water enters the tank filled with cation resin, all the positively charged cations are attracted by the cation resin beads and exchanged for hydrogen. The anions with negative charge will not be attracted and pass through the cationic resin beads. For example, let’s check the calcium chloride in the feed water. In solution, calcium ions are positively charged and attach themselves to the cationic beads to release hydrogen ions. Chloride has a negative charge, so it does not attach itself to the cationic resin beads. Hydrogen with positive charge attaches itself to chloride ion to form hydrochloric acid (HCl). The resulting effluent from the sac exchanger will have a very low pH and a much higher conductivity than the incoming feed water.

The effluent of cationic resin is composed of strong acid and weak acid. Then, the acid water will enter the tank filled with anion resin. Anionic resins will attract negatively charged anions such as chloride ions and exchange them for hydroxyl groups. The result is hydrogen (H +) and hydroxyl (OH -), which form H2O

In fact, due to “sodium leakage”, the mixed bed system will not produce real H2O. If sodium leaks through the cation exchange tank, it combines with hydroxyl to form sodium hydroxide, which has high conductivity. Sodium leakage occurs because sodium and hydrogen have very similar attraction to cationic resin beads, and sometimes sodium ions do not exchange hydrogen ions themselves.

In the mixed bed system, strong acid cation and strong base anion resin are mixed together. This effectively enables the mixed bed tank to function as thousands of mixed bed units in a tank. The cation / anion exchange was repeated in a resin bed. Due to a large number of repeated cation / anion exchange, the problem of sodium leakage was solved. By using a mixed bed, you can produce the highest quality deionized water.

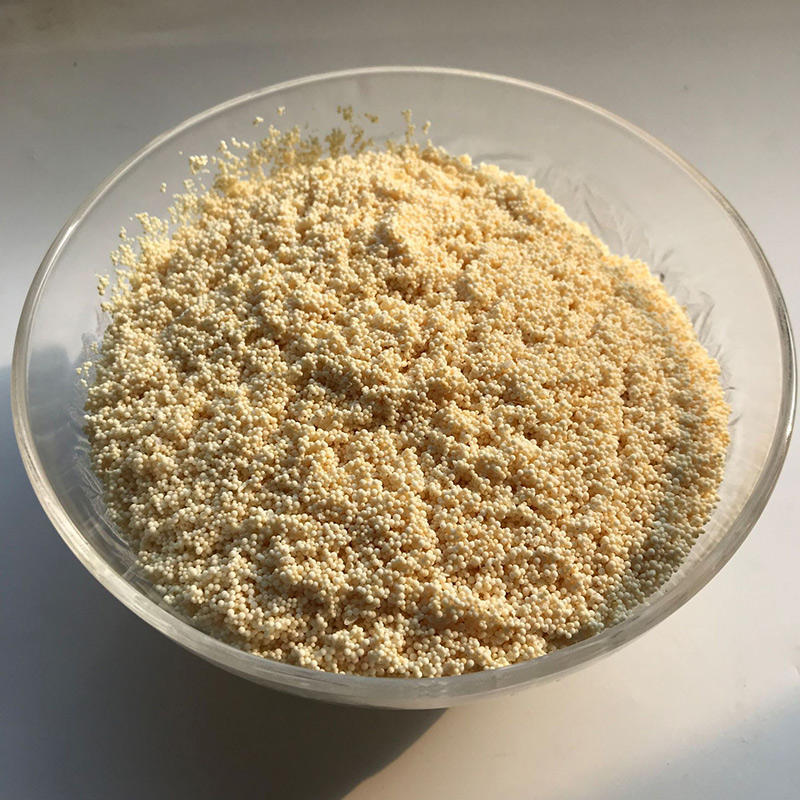

Product detail pictures:

Related Product Guide:

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for Wholesale China Mixed Bed Deionizer Company Factories - Mixed Bed Resin – Dongli , The product will supply to all over the world, such as: Indonesia, Swansea, Sacramento, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.