Wholesale China Ion Exchange Resin Comparison Chart Companies Factory - Strong base anion exchange resin – Dongli

Wholesale China Ion Exchange Resin Comparison Chart Companies Factory - Strong base anion exchange resin – Dongli

Wholesale China Ion Exchange Resin Comparison Chart Companies Factory - Strong base anion exchange resin – Dongli Detail:

Strong Base Anion Resins

| Resins | Polymer Matrix Structure | Physical Form Appearance | FunctionGroup |

Ionic Form |

Total Exchange Capacity meq/ml | Moisture Content | Particle Size mm | SwellingCl→OH Max. | Shipping Weight g/L |

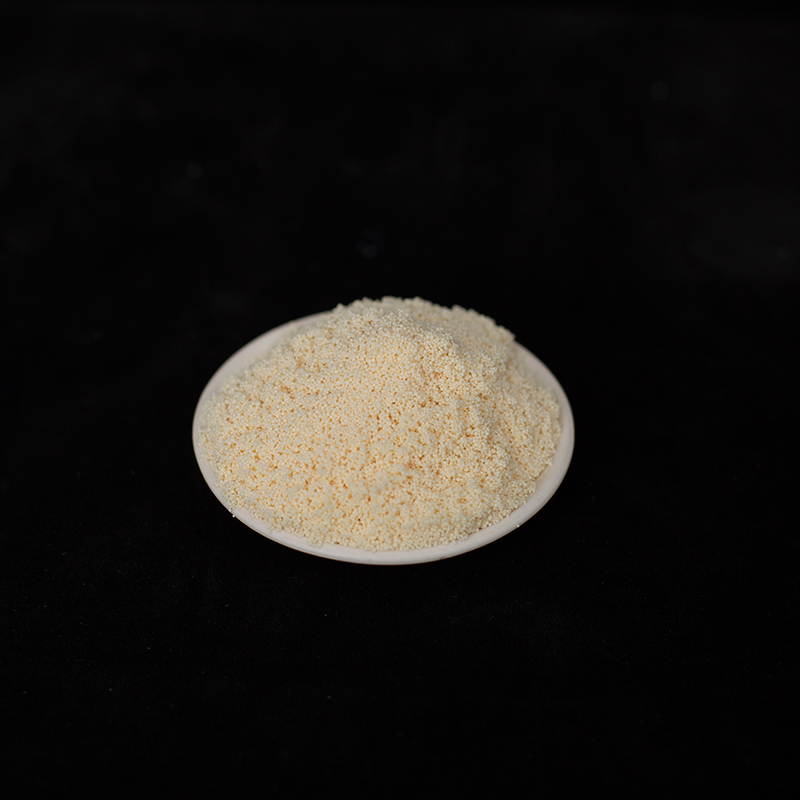

| GA102 | Gel Type I ,Poly-Styrene with DVB | Clear to Slight Yellow Spherical Beads | R-NCH3 |

Cl |

0.8 | 65-75% | 0.3-1.2 | 20% | 670-700 |

| GA104 | Gel Type I ,Poly-Styrene with DVB | Clear to Slight Yellow Spherical Beads | R-NCH3 |

Cl |

1.10 | 55-60% | 0.3-1.2 | 20% | 670-700 |

| GA105 | Gel Type I ,Poly-Styrene with DVB | Clear to Slight Yellow Spherical Beads | R-NCH3 |

Cl |

1.30 | 48-52% | 0.3-1.2 | 20% | 670-700 |

| GA107 | Gel Type I ,Poly-Styrene with DVB | Clear to Slight Yellow Spherical Beads | R-NCH3 |

Cl |

1.35 | 42-48% | 0.3-1.2 | 20% | 670-700 |

| GA202 | Gel Type II ,Poly-Styrene with DVB | Clear to Slight Yellow Spherical Beads | R-N(CH3)2(C2H4OH) |

Cl |

1.3 | 45-55% | 0.3-1.2 | 25% | 680-700 |

| GA213 | Gel , Poly-Acrylic with DVB | Clear Spherical Beads | R-NCH3 |

Cl |

1.25 | 54-64% | 0.3-1.2 | 25% | 780-700 |

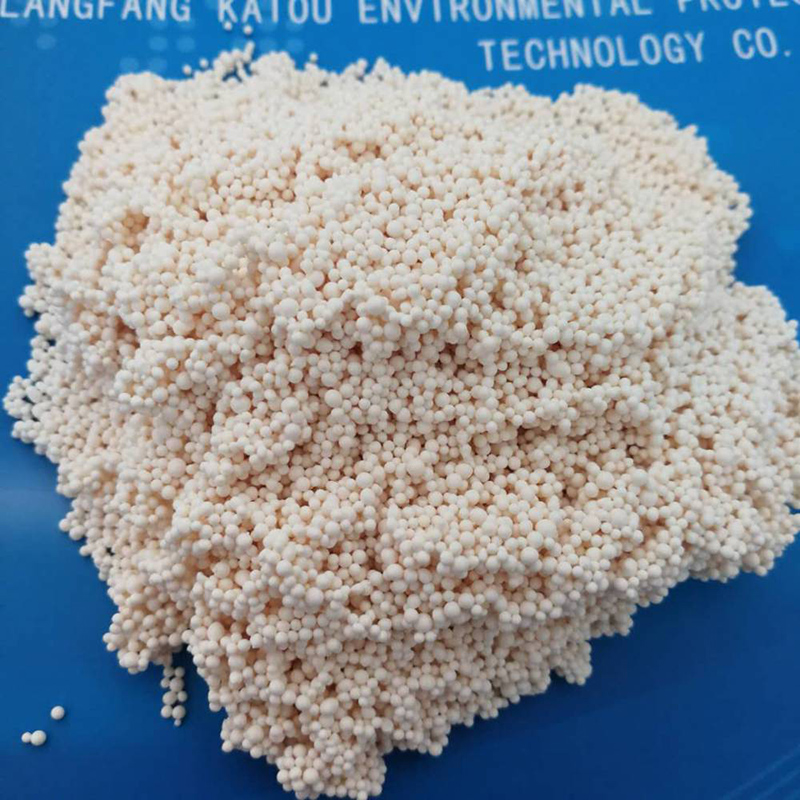

| MA201 | Macroporous Type I Polystyrene with DVB | Opaque Beads | Quaternary Ammonium |

Cl |

1.20 | 50-60% | 0.3-1.2 | 10% | 650-700 |

| MA202 | Macroporous Type II Polystyrene with DVB | Opaque Beads | Quaternary Ammonium |

Cl |

1.20 | 45-57% | 0.3-1.2 | 10% | 680-700 |

| MA213 | Macroporous Poly-Acrylic with DVB | Opaque Beads | R-NCH3 |

Cl |

0.80 | 65-75% | 0.3-1.2 | 25% | 680-700 |

Precautions In Use

1. Keep a certain amount of water

Ion exchange resin contains a certain amount of water and should not be stored in the open air. During storage and transportation, it should be kept moist to avoid air drying and dehydration, resulting in broken resin. If the resin is dehydrated during storage, it should be soaked in concentrated salt water (25%), and then diluted gradually. It should not be directly put into water, so as to avoid rapid expansion and broken resin.

2. Keep a certain temperature

During storage and transportation in winter, the temperature should be kept at 5-40 ℃ to avoid supercooling or overheating, which will affect the quality. If there is no thermal insulation equipment in winter, the resin can be stored in salt water, and the concentration of salt water can be determined according to the temperature.

3. Impurity removal

The industrial products of ion exchange resin often contain a small amount of low polymer and non reactive monomer, as well as inorganic impurities such as iron, lead and copper. When the resin is in contact with water, acid, alkali or other solutions, the above substances will be transferred into the solution, affecting the quality of effluent water. Therefore, the new resin must be pretreated before use. Generally, water is used to make the resin fully expand, and then, The inorganic impurities (mainly iron compounds) can be removed by 4-5% dilute hydrochloric acid, and the organic impurities can be removed by 2-4% dilute sodium hydroxide solution. If it is used in pharmaceutical preparation, it must be soaked in ethanol.

4. Regular activation treatment

In use, the resin can be prevented from being gradually diluted with metal (such as iron, copper, etc.) oil and organic molecules. The anion resin is easy to be polluted by organic matters. It can be soaked or rinsed with 10% NaC1 + 2-5% NaOH mixed solution. If necessary, it can be soaked in 1% hydrogen peroxide solution for a few minutes. Other methods can also be used, such as acid alkali alternate treatment, bleaching treatment, alcohol treatment and various sterilization methods.

Product detail pictures:

Related Product Guide:

We attempt for excellence, provider the customers", hopes to be the most beneficial cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes value share and continuous advertising for Wholesale China Ion Exchange Resin Comparison Chart Companies Factory - Strong base anion exchange resin – Dongli , The product will supply to all over the world, such as: Guatemala, Kuala Lumpur, Cairo, Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!