Wholesale China Ion Exchange Resin Beads Companies Factory - Weak base anion exchange resin – Dongli

Wholesale China Ion Exchange Resin Beads Companies Factory - Weak base anion exchange resin – Dongli

Wholesale China Ion Exchange Resin Beads Companies Factory - Weak base anion exchange resin – Dongli Detail:

Strong Base Anion Resins

| Resins | Polymer Matrix Structure | Physical Form Appearance | FunctionGroup | Ionic Form | Total Exchange Capacity meq/ml | Moisture Content | Particle Size mm | SwellingFB→Cl Max. | Shipping Weight g/L |

| MA301 | Macroporous Ploy-styrene with DVB | Opaque White Spherical Beads | Tertiary Amine | Free Base | 1.4 | 55-60% | 0.3-1.2 | 20% | 650-700 |

| MA301G | Macroporous Poly-Styrene with DVB | White Spherical Beads | Tertiary Amine | Cl- | 1.3 | 50-55% | 0.8-1.8 | 20% | 650-690 |

| GA313 | Gel type Poly-acrylic with DVB | Transparent Spherical Beads | Tertiary Amine | Free Base | 1.4 | 55-65% | 0.3-1.2 | 25% | 650-700 |

| MA313 | Macroporous Poly-acrylic with DVB | White Spherical Beads | Tertiary Amine | Free Base | 2.0 | 48-58% | 0.3-1.2 | 20% | 650-700 |

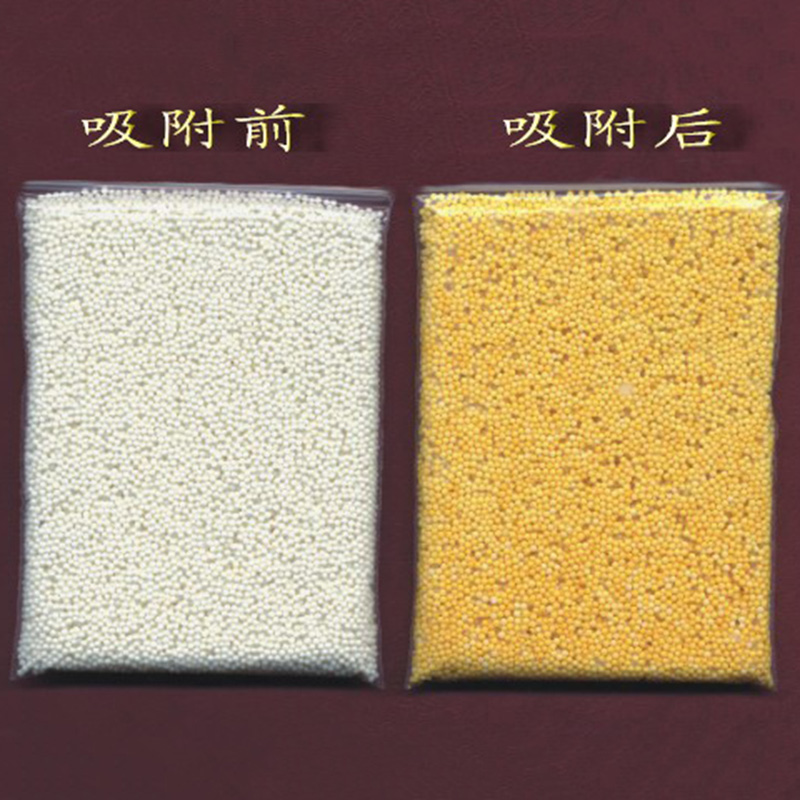

Impurity Removal

The industrial products of ion exchange resin often contain a small amount of low polymer and non reactive monomer, as well as inorganic impurities such as iron, lead and copper. When the resin is in contact with water, acid, alkali or other solutions, the above substances will be transferred into the solution, affecting the quality of effluent water. Therefore, the new resin must be pretreated before use. Generally, water is used to make the resin fully expand, and then, The inorganic impurities (mainly iron compounds) can be removed by 4-5% dilute hydrochloric acid, and the organic impurities can be removed by 2-4% dilute sodium hydroxide solution. If it is used in pharmaceutical preparation, it must be soaked in ethanol.

Periodic Activation Treatment

In the use of resin, it is necessary to prevent contact with oil pollution, organic molecular microorganism, strong oxidant and other metals (such as iron, copper, etc.) so as to avoid reducing ion exchange capacity or even losing function. Therefore, the resin must be activated irregularly according to the situation. The activation method can be determined according to the pollution condition and conditions. Generally, the cation resin is easy to be polluted by Fe in softening by hydrochloric acid immersion, Then dilute gradually, the anion resin is easy to be polluted by organic matter. It can be soaked or washed with 10% NaCl + 2-5% NaOH mixed solution. If necessary, it can be soaked in 1% hydrogen peroxide solution for several minutes. Other, can also use acid-base alternate treatment, bleaching treatment, alcohol treatment and various sterilization methods.

New Resin Pretreatment

Pretreatment of new resin: in industrial products of ion exchange resin, there are a small amount of oligomers and monomers that do not participate in the reaction, and also contain inorganic impurities such as iron, lead and copper. When the resin contacts water, acid, alkali or other solution, the above substances will be transferred into the solution, which will affect the quality of the effluent. Therefore, the new resin must be pre treated before use. Generally, the resin will expand with water, and then the inorganic impurities (mainly iron compounds) can be removed by 4-5% dilute hydrochloric acid, and the organic impurities can be removed by 2-4% dilute sodium hydroxide solution to be washed to near neutral.

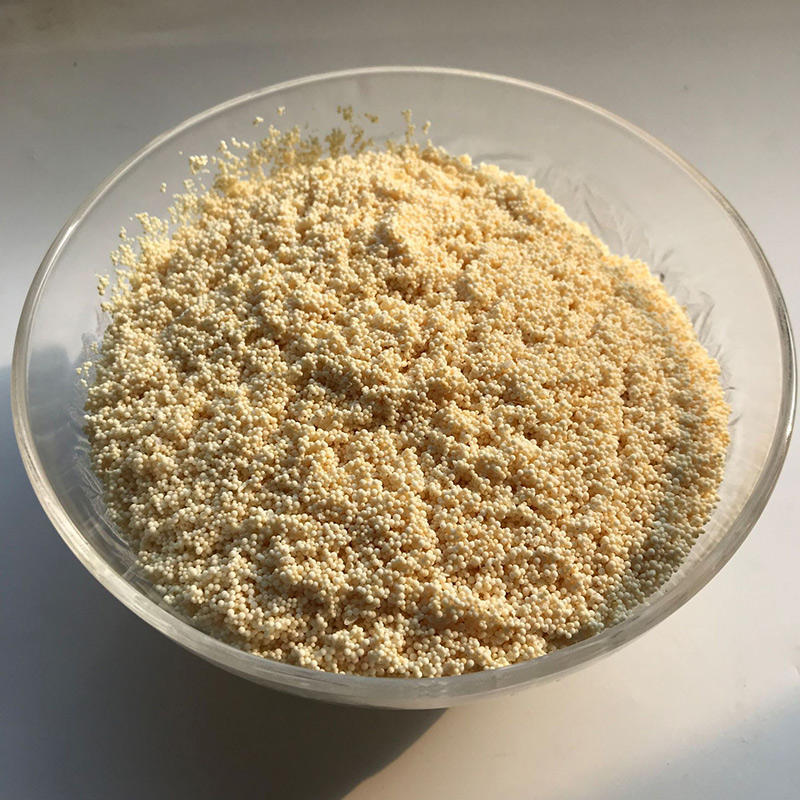

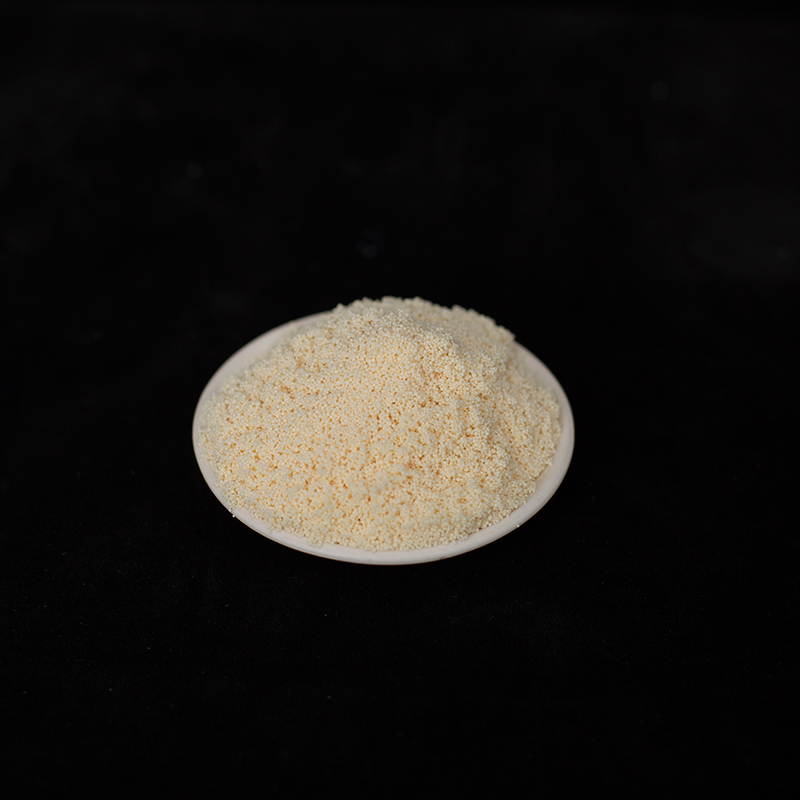

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for Wholesale China Ion Exchange Resin Beads Companies Factory - Weak base anion exchange resin – Dongli , The product will supply to all over the world, such as: Malaysia, Sierra Leone, Iran, We've more than 10 years exported experience and our products and solutions have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!