Wholesale China Dowex Ion Exchange Resin Manufacturers Suppliers - Macroporous Adsorptive Resins – Dongli

Wholesale China Dowex Ion Exchange Resin Manufacturers Suppliers - Macroporous Adsorptive Resins – Dongli

Wholesale China Dowex Ion Exchange Resin Manufacturers Suppliers - Macroporous Adsorptive Resins – Dongli Detail:

Marcrooporous Adsorption Resin

| Resins | Polymer Matrix Structure | Physical Form Appearance | Surface nArea m2/g | Average Pore Diameter | Adsorption Capacity | Moisture Content | Particle Size mm | Shipping Weight g/L |

| AB-8 | Macroporous Ploy-styrene with DVB | Opaque White Spherical Beads | 450-550 | 103 nm | 60-70% | 0.3-1.2 | 650-700 | |

| D101 | Macroporous Poly-Styrene with DVB | Opaque White Spherical Beads | 600-700 | 10 nm | 53-63% | 0.3-1.2 | 670-690 | |

| D152 | Macroporous Pype Poly-acrylic with DVB | Opaque White Spherical Beads | Na/H | 1.4 meq.ml | 60-70% | 0.3-1.2 | 680-700 | |

| H103 | Post Crosslink styrene with DVB | Dark brown to black Spherical | 1000-1100 | 0.5-1.0TOC/g100mg/ml | 50-60% | 0.3-1.2 | 670-690 |

Macroporous adsorption resin is a kind of polymer adsorption resin without exchange group and macroporous structure. It has good macroporous network structure and large specific surface area. It can selectively adsorb organic matter in aqueous solution through physical adsorption. It is a new type of organic polymer adsorbent developed in the 1960s. It has been widely used in environmental protection, food, medicine and other fields.

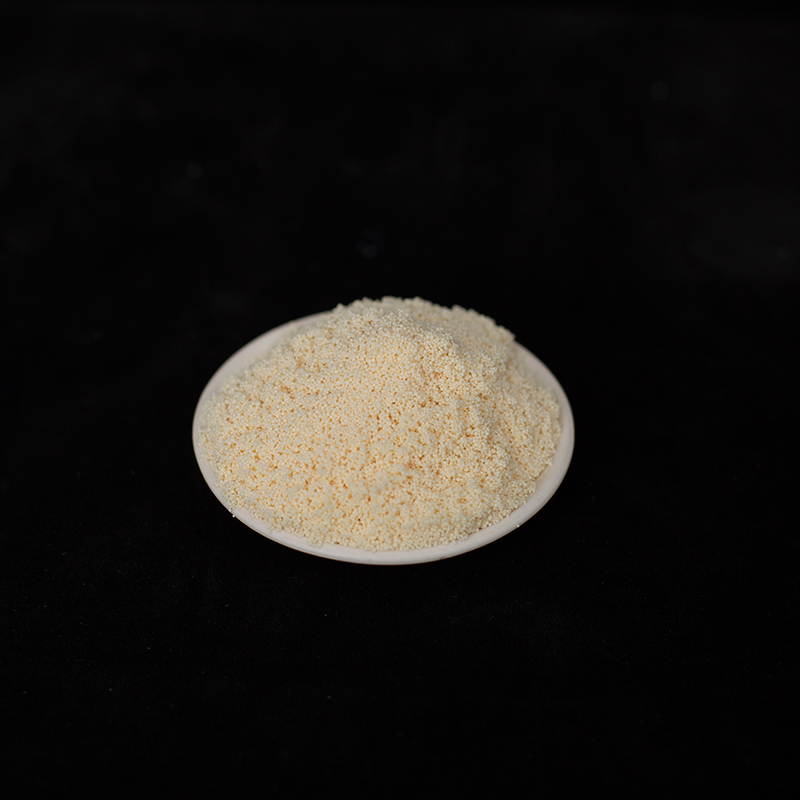

Macroporous adsorption resin is generally white spherical particles with particle size of 20-60 mesh. The macrospheres of macroporous adsorption resin are composed of many micro spheres with holes in each other.

Macroporous adsorption resin was polymerized with styrene, divinylbenzene, etc. in 0.5% gelatin solution and a certain proportion of porogen. Styrene was used as monomer, divinylbenzene as crosslinking agent, toluene and xylene as porogens. They were crosslinked and polymerized to form the porous framework structure of macroporous adsorption resin.

The selection of adsorption and desorption conditions directly affects the quality of the adsorption process of macroporous adsorption resin, so various factors should be considered in the whole process to determine the best adsorption and desorption conditions. There are many factors affecting resin adsorption, such as the properties of separated components (polarity and molecular size), the properties of loading solvent (solubility of solvent to components, salt concentration and pH value), the concentration of loading solution and adsorption water flow rate.

Generally, the larger polar molecules can be separated on the medium polar resin, and the smaller polar molecules can be separated on the non-polar resin; The larger the volume of the compound, the larger the pore size of the resin; The adsorption capacity of resin can be increased by adding appropriate amount of inorganic salt into the loading solution; Acidic compounds are easy to be adsorbed in acidic solution, basic compounds are easy to be adsorbed in alkaline solution, and neutral compounds are easy to be adsorbed in neutral solution; Generally, the lower the concentration of loading solution, the better the adsorption; For the choice of dropping rate, it is better to ensure that the resin can fully contact with the loading solution for adsorption. The factors affecting the desorption conditions include the type of eluent, concentration, pH value, flow rate, etc. The eluent can be methanol, ethanol, acetone, ethyl acetate, etc. Different eluent and different eluent concentration should be selected according to the adsorption capacity of different substances on the resin; By changing the pH value of the eluent, the molecular form of the adsorbent can be changed, and it is easy to elute; The elution flow rate is generally controlled at 0.5-5ml/min.

The pore size and specific surface area of macroporous adsorption resin are relatively large. It has three-dimensional three-dimensional pore structure inside the resin, which has many advantages such as high physical and chemical stability, large specific surface area, large adsorption capacity, good selectivity, fast adsorption speed, mild desorption conditions, convenient regeneration, long service cycle, suitable for closed circuit cycle and cost saving.

Product detail pictures:

Related Product Guide:

The organization upholds the philosophy of "Be No.1 in good quality, be rooted on credit history and trustworthiness for growth", will keep on to provide previous and new customers from home and overseas whole-heatedly for Wholesale China Dowex Ion Exchange Resin Manufacturers Suppliers - Macroporous Adsorptive Resins – Dongli , The product will supply to all over the world, such as: Estonia, Vancouver, Jordan, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.